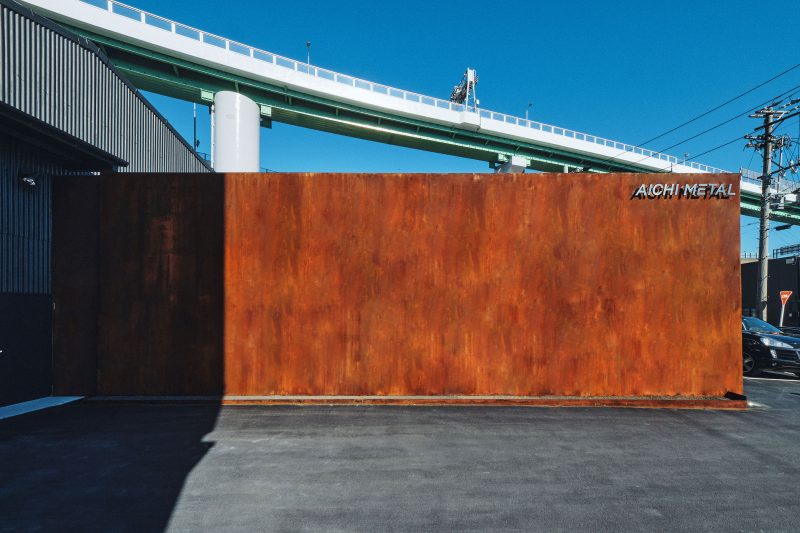

AICHI METAL

Technical Case Studies

The topcoat agent we used until around 2020 had no quality problems, but the hardness of the coating film was soft for our needs for a variety of surface decoration treatments, and the coating film was prone to scratches. Of course, this all happens in the process and there is no problem with the final finished product. However, it was difficult for the calculated decoration to occur in the process and a lot of processing effort was required, so we continued our research for improvement. Therefore, we conducted several simultaneous demonstrations of higher coating film hardness. Various methods were put into practice, but the most important was the cold-heat cycle test. This is a process of alternating hot and cold water exposure, and as a test it is very simple. However, it requires patience, as the time and number of tests are changed while judging the progress along the way.

Improved operational efficiency from the topcoat

The results of trying several different materials and topcoat agents were obvious. The different types gave the expected results. The materials prepared were black leather iron sheets and SUS304 iron sheets, each with about 20 sheets. The thickness of the paint film was also measured in detail, as well as a detailed study of how each paint film varied. The result was the adoption of a new topcoating agent and updates in terms of process control and technology based on the material. Today, the introduction of the new system has already been completed and is highly effective.