Aichi (Aichi Prefecture)

Research and Development

Corrosion and metals

Metals are often thought of as stable materials when they are finished, but in fact they are more stable when combined with other substances. This is confusing information for a moment. Iron, for example, begins to seek oxygen and oxidise after it has been refined. It is covered in rust and decays naturally. This is called metal corrosion. This is the moment when we realise that nature is really an amazing mechanism. However, this is not good for metal materials used in human society. The key is how to prevent corrosion and prolong the life of the metal. It is no exaggeration to say that modern society would not be able to do without metal, and if metal structures were to last only a few years, the very foundations of civilisation would be shaken. This is how various metals are refined and alloyed in human society, and new materials are still being created.

What is weathering steel sheet (henceforth ‘Corten steel’)?

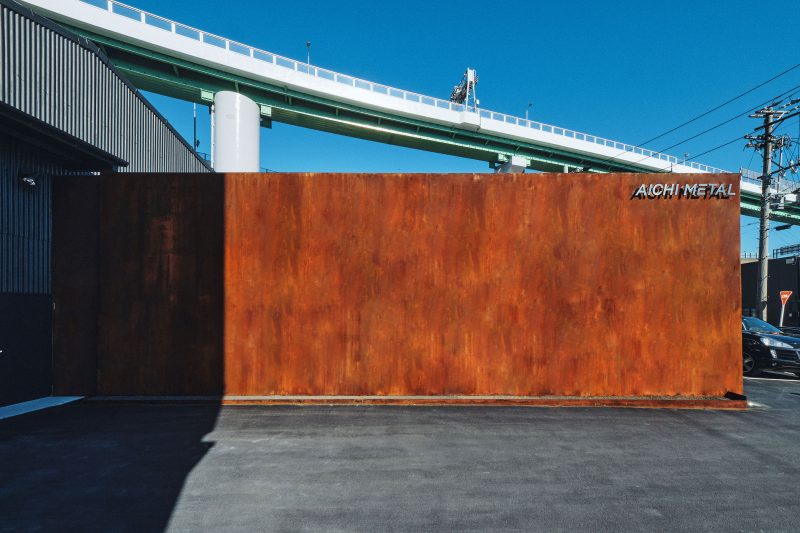

Are you familiar with Corten steel, a steel material known as weatherproof steel sheet? It is one of the most famous materials. It is a material that has succeeded in making its strength as a steel material incredibly long-lasting by daring the surface to rust, thereby stabilising it and blocking it from the core material and the outside air. At first glance, it looks like a rusted object, but inside it is kept as a brand new material. Rust is highly popular as a design feature. However, being a corrosive reaction, rust makes the metal itself brittle. It is fair to say that the appearance of Corten steel played a major role in making these contradictory elements possible. It is one of the materials that we at AICHI METALS are familiar with. On the other hand, it is naturally all metal and therefore quite heavy, which in turn makes it difficult to reduce weight.

Design rust and natural rust

Using the VeroMetal technology at AICHI METAL, it is possible to create wooden boards with a metallic paint on the surface to create rust, or plastic can be used. To achieve strength, the surface can be treated with a honeycomb core. Therefore, it is possible to make gates and doors that look like Corten steel but are lighter in weight. However, natural rust and design rust have very different finishes. Natural rust has an uneven and decadent appearance, whereas design rust has a uniform rust finish that gives the impression of high quality in terms of colour and texture. Technique is required to successfully produce this design rust and to make it appear on the entire surface or in parts. It is very difficult to achieve a stable rust design.

Rust and design with thermal spray technology

When we produce rust, we use metallic paints for all kinds of materials. For this reason, we actively use polishing and thermal spraying techniques. First of all, depending on the surface finish, the rust can be extremely uneven. These can be adjusted and made as flat as possible, or conversely, if the order is for an uneven surface, we will do so. Furthermore, the external environment has a major influence on rusting on external walls, if not on internal walls. If it rains, water will find its way through the wall. At these times, we want to prevent the metal paint from peeling off the surface anyway. This is where thermal spray technology is applied. The base material is sprayed to create a pear-like surface, which is then coated with the paint to create a tight, interlocking finish that largely prevents the paint from peeling off. In this way, rust like Corten steel is produced consistently on any material. Nevertheless, quality is still a way off. With continuous improvements, we will continue to work towards achieving a finish and design quality that makes it look as if it is a new material.