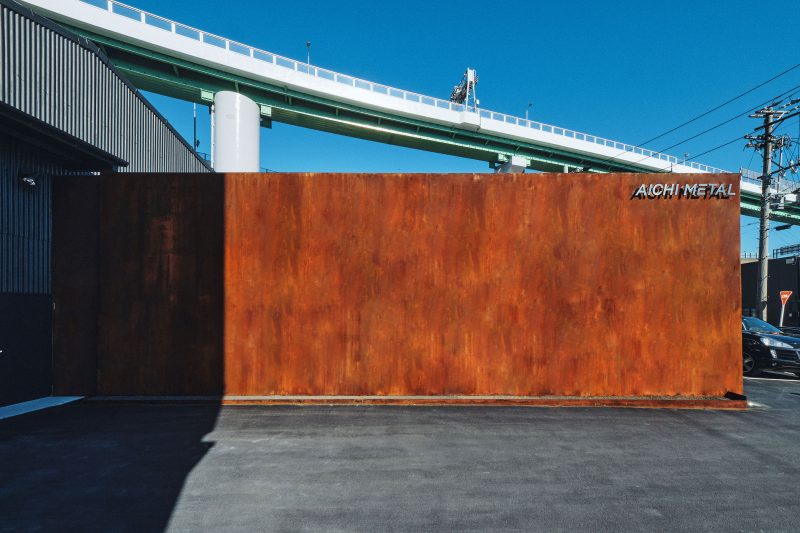

Aichi (Aichi Prefecture)

For AICHI METALS, precision is extremely important. Accuracy can be defined in many different ways. In housing, the gates and window frames that we provide are made to the precision that was achieved at the time of manufacture by adjusting the slight errors in precision that occur as a result of the assembly of the house through on-site execution. In a sense, the accuracy indicated at the time of manufacture is adjusted on site, but this, too, requires skill to master and adjust the accuracy. On the other hand, the accuracy required for the manufacture of industrial girders and frames, which play a supporting role in the installation of industrial equipment and precision machinery, is, so to speak, a kind of standardisation. The accuracy required for the platforms on which industrial equipment is installed is the same as the accuracy required for what is mounted and utilised on top of it. If this is the case, even deviations of a few tenths of a millimetre are unacceptable.

Improved efficiency in girders and frame fabrication and operations

Digital equipment can now be useful in the trial-and-error process of building and setting up the frames and mounts of precision and industrial equipment according to their intended use. Traditionally, the techniques required include the use of rulers, calipers, etc., and the ability to calculate errors and assemble them by mastering the tolerances on the design drawings, material distortion and expansion/contraction, and by determining the conditions under which they will be assembled and used. Furthermore, it is also necessary to consider the possibility of moving the installed equipment. Although we do not have enough knowledge to support the use of gyros and other advanced equipment, it may eventually be necessary to respond to such needs. It is also important to shape the system with a view to improving the efficiency of the operator’s work.

Trestles as tools

This is how the trestles used as ‘tools’ are built up. As a matter of course, it is not just a matter of assembling the materials. Functional aspects such as high strength and safety are important, and usability is equally important. This is true even for the simple products we make, such as the one in the picture. It is not difficult to imagine the level of precision and technology that is required for buildings in advanced industries that handle more precise equipment. I think it is important to understand that in industrially advanced countries, such technology exists and advanced equipment is operated on top of it. What we make is only a small skeleton, but every time we make it, we feel such a sense of awe. At the same time, it is a job that reminds us that it is not a distant field, but that it is important for us to feel and learn the essence of it as well.

New possibilities for metal products as supporting actors.

We can find new possibilities for metal not only as the face of housing and architecture, but also as a supporting role in the production of industrial equipment and frames for girders.