熟練の手仕事

弊社には、この道を極めた熟練工がいます。若手技術者からの信頼も厚く、ものづくりにかける情熱と技術の伝播が常に行われています。

アイチ金属が保有するさまざまな技術機器についてご紹介しています

弊社には、この道を極めた熟練工がいます。若手技術者からの信頼も厚く、ものづくりにかける情熱と技術の伝播が常に行われています。

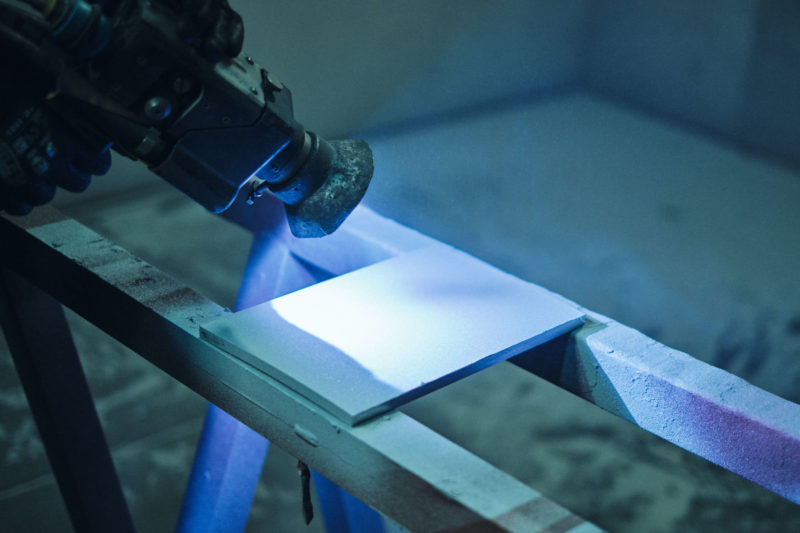

金属を組み上げ、接合部を綺麗に整えていく。この基礎こそに私たちの創業の思いがあります。

鈑金屋としてのコア技術のひとつです。弊社では、強度と精度にこだわっています。

基本中の基本ですが、弊社はこだわっています。結局、バリがひとつあれば品質はまるっとダメになるのです。

溶接面を目に見える部分に残さない金属組みを実現します。強度はもちろん、美しい金属素材部材に仕上がります。

蔦のような姿をした鉄製の柵や、複雑形状の手すりなど、豊かな形状オーダーにいつでもお応えできます。

弊社では様々な磨き加工が可能です。鏡面、マット面、ヘアラインなど。高度な職人技の領域です。

表面に細かな凹凸を作っていきます。後工程の塗装のための下処理です。

亜鉛を金属面(鉄)に吹き付ける防蝕処理です。犠牲防蝕と言い、水に溶けやすい亜鉛が鉄の犠牲になって守る錆止め工法です。

金属への塗装の最高峰は何か?

考えた結果、自動車鈑金塗装にたどり着きました。

弊社の塗装は、そのノウハウと材料を導入しています。

金属塗装に求められる色合いは、その多くが、金属の素材感を活かした黒系統の色になります。

弊社では、そのオーダーも独自の調色で再現しています。

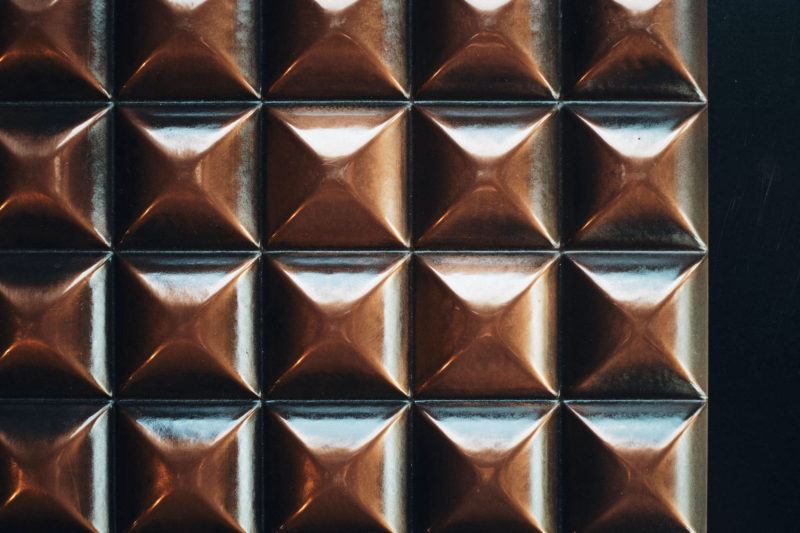

メタルコーティングは液状化された金属なので、凹凸のある面材にも美しい仕上がりで応えます。

凹凸面加飾同様、丸みを帯びた面材にも美しい仕上がりで応えます。

メタルコーティングしたのちに、研磨処理を繰り返し、光沢を出していきます。

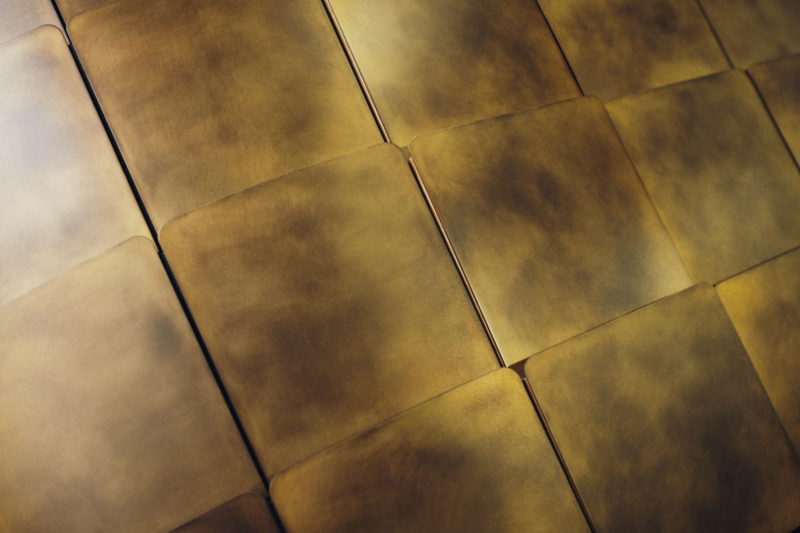

金属素材は時を経ることにより、より魅力的に変化していきます。

エイジング加工はそれを意図的に再現していく技術です。

金属、木材、革、プラスチック、アクリル等々。メタルコーティングは、どんな素材にもコーティングすることが可能です。

メタルコーティングを厚塗りすることで、テクスチャを強調することが可能です。

日本の伝統素材である漆と金属を組み合わせました。モダンな印象です。

ストーンテクスチャのような加飾技法であるリン酸処理も豊富な実績があります。

同時に、後工程での重要な補修もおまかせください。

鉄赤錆を使うことは、流れ錆の問題等、一般的に難しいと言われています。

弊社では、耐候性鋼鈑をはじめLiquid Metal・溶射など、お客様のニーズに合わせたご提案をさせて頂きます。

当社で扱う金属は、鉄・鉛・ステンレス・アルミ・銅・真鍮など、金属の性質を理解しているので、仕上がりは無限です。

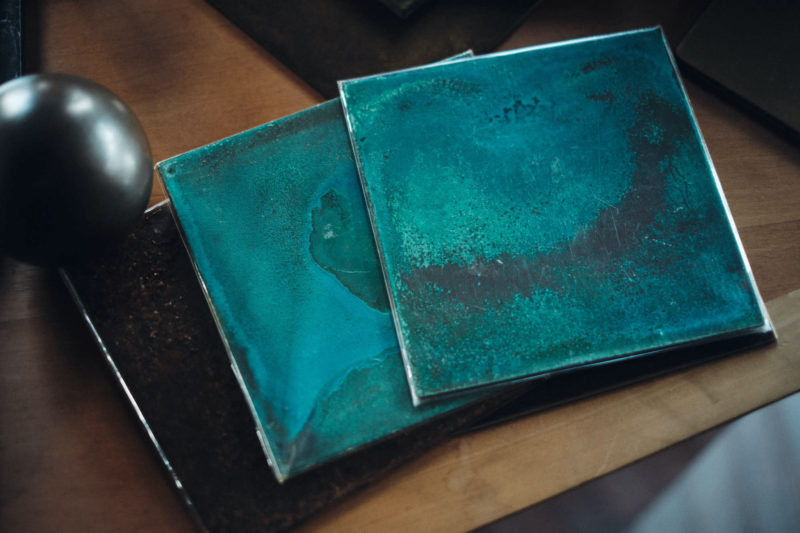

銅という金属は、殺菌効果もあり近年注目されている金属です。

弊社では、この殺菌効果を利用した手摺や取手等のご提案もしています。

真鍮という金属は、使い込むほどに黒く渋みを帯びた味を醸し出します。

弊社では、このように経年変化した様子を再現できます。

基材に溶かした金属を吹き付けていきます。凹凸や平滑にしたり、極めて耐久性の高い処理が実現します。

弊社では、加飾処理したのちに酸化防止剤に浸漬させることで、加飾した部分の酸化が進まないように処理します。

さらに様々なコーティングで表面強度を高めることをしております。

銅錆びである緑青には歴史の匂いが出ます。とはいえ毒性が強い緑青の加飾にも適切な表面処理が求められます。

金属粉を利用することで、建築金属製品への加飾性を飛躍的に向上させました。

従来のビス・ボルトの頭は時に製品の仕上がりを損なわせてしまいます。弊社独自の「擦り消しビス(ボルト)」を使用することで金属の美観を損なわず、接合部分を頑丈に固定することが出来ます。

弊社では、オリジナルの金属酸化処理剤の研究も進めています。

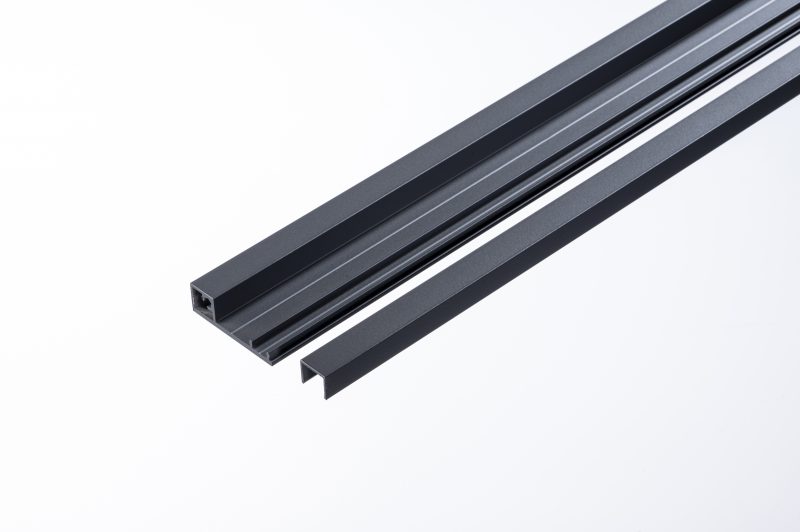

弊社の歴史は窓サッシ造作からスタートしました。現代ではより美しい仕上がりのスチールサッシフレーム製作に特化しております。その歩みから生まれた新たな商品がこの「ALGRID」です。(実用新案登録製品)