Tokyo

Technological Development

High-end thermal spray finish products

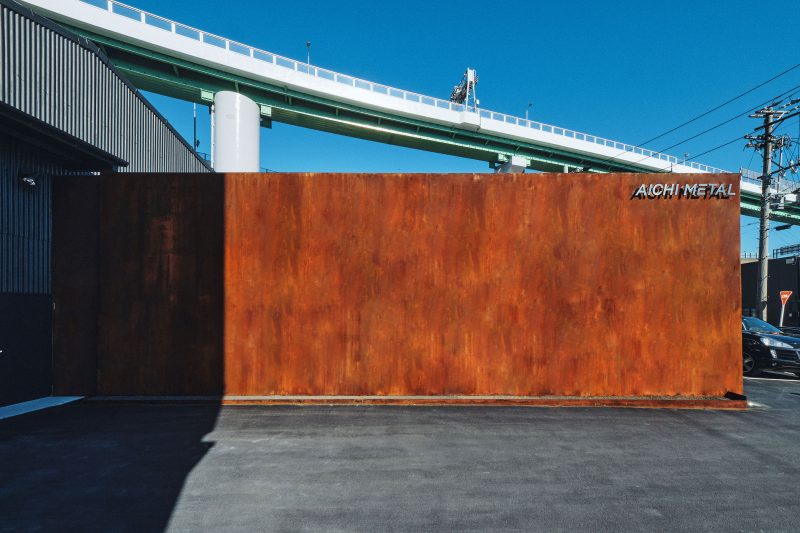

In metal decoration, the variety of expression is attractive. There are various ways of creating a look, but the most common are gloss by polishing, intentional lines by grinding and discolouration by chemical reactions, such as a shimmering effect. Among these, the method of creating textures on the surface is popular as a way of creating a complex expression, such as a completely new look on the metal or unevenness when light hits it. However, surfaces that are simply created can easily peel off due to environmental factors, or come off with the slightest impact. In this context, thermal spraying technology is used to spray molten metal, which not only provides sacrificial corrosion protection with zinc, but also allows for a high quality product with design appeal, which is why we have refined this technology.

Type of polished finish

Thermal spray treatment is not a patent of our company and has long been popular in the construction and shipbuilding fields in order to improve corrosion resistance and strength. However, as the capital investment in the field of decorative treatment is to a certain extent large, it has a history of not being considered due to cost considerations. In our company, we have already tried this more than five years ago. We have been carrying out a lot of technical trial-and-error and research, including on equipment, and have been studying the thermal spray treatment in the decorative field. There is a wide variety of metal surfaces that can be created by thermal spraying. The roughness and fineness alone vary from cast metal to sharkskin and yuzu (citron) skin. If brush finishing, decoration and polishing are applied, the unevenness of the sprayed surface becomes a pattern as it is, giving it a rich expression. In addition, combining painting and other techniques provides unlimited expressive power. Furthermore, the extremely high strength of the thermal spraying provides excellent durability.

A metal line-up that broadens the range of design possibilities

Thermal spraying involves spraying hot metal, which may distort or melt some materials. Nevertheless, it can be used on a wide range of materials as long as the counterpart is metal. Examples include copper, brass, bronze, aluminium, stainless steel and iron. The important thing is the sealing process. In the case of stainless steel, for example, it is not necessary to be that careful, as the original material does not rust, but in the case of iron, it is necessary to improve the corrosion performance. Therefore, if careful sealing is not carried out at the same time as the decorative treatment, there is an increased risk of rusting and corrosion from weathering. Of course, we have carried out research and development in these areas and have now achieved a virtually problem-free treatment. The possibilities for decoration and thermal spraying are endless. However, it is also a process that is difficult to apply unless everything is in place – equipment, research, practice and improvement.