Nagoya City, Aichi Prefecture

Phosphatization

Phosphating is a relatively popular technology in the metal decoration field. It produces a quartz-like, stone-like decorative expression on metal surfaces, providing a modern, smart impression. In the past, it was often used on the facades of relatively large buildings, but nowadays it is also popular for use on residential gates. However, because it is so popular, it is difficult to treat, and especially when durability is important, there is a tendency for problems to occur if it is not done by a professional. The request that came to our company this time was exactly such a case. The site had not been phosphatised followed by a solid surface coating, so it was unable to withstand rainwater and moisture, and the surface had turned white and dirty. This is a trend that is quite common these days, but it can be attributed to a lack of knowledge and research by the contractor who first worked on the project. However, it is not only the contractor’s fault. Solid construction costs money. Lack of knowledge on the part of the ordering party can also be an important point.

Difficult in some repairs

Now, for this repair, it is best to redo the whole surface. The project looked like it could be partially repaired, but the phosphate-treated areas absorb light. However, if the paint is applied, the light is repelled only in that area. In other words, only the repaired areas treated with paint stand out, as if an adhesive plaster had been applied. Originally, after galvanising, phosphating and then selecting the best coating from a variety of coatings as a white rust-preventive treatment, it would be difficult to select a partial repair, as the entire process is carried out on the spot, and one can only imagine where the missing parts are. So we tried a new method, which we have been researching, and which we have found to be very effective.

Textures produced

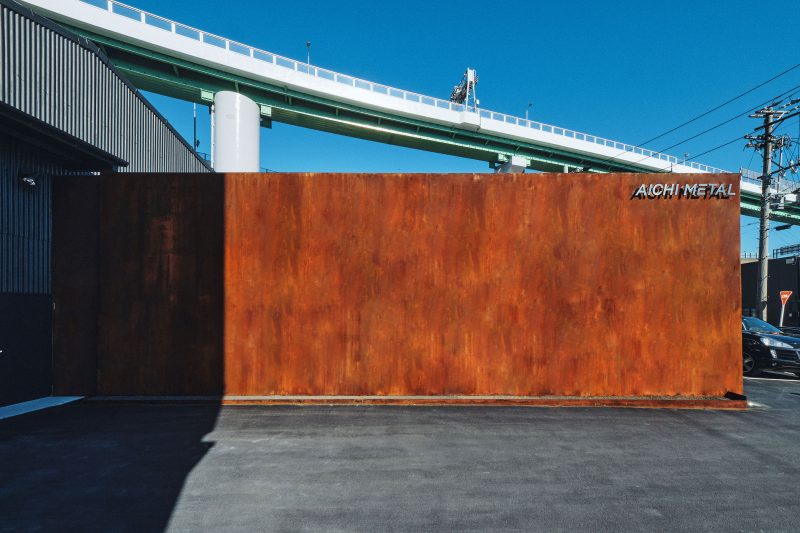

First, the zinc is sprayed with VeroMetal zinc. At this point, you should have several colours of zinc made and ready. And then you prepare some stencils. Yes, that is, you paint it. The only way to do this is to redo the phosphatised components, as a matter of fact, but this time they were already installed on the exterior of the house. So we treated them in a way that created a colour and ‘made’ the same texture. The zinc in VeroMetal is not painted, but the metal itself, so the same texture can be created as in the phosphatised areas. In this case, this allowed us to create an almost perfectly indistinguishable repair. This method is something we have been researching for some time. At AICHI METALS, we do a lot of research on a daily basis. We are living it at various sites and will introduce it to you again.