Takasaki City

Case Studies

A few years ago, we worked on the internal theatre balustrade of an arts and culture centre in a regional city. The finish is metallised with VeroMetal. The structure is not metal, but a material whose strength and operation are important, but a metallic look was required for the design performance when installed in the space. The tonal metal has a strong presence in the light space with plenty of wood. What is important about this case for us is not the difficulty of the handrail itself, but the fact that it required quality and process control in terms of quantity: ‘a certain amount of material of the same quality must be provided’.

Mass production processes and craftsmanship

Our work is often special orders, which start with the design of the building and the creation of a design to be incorporated into the actual metal components. While following the intent of the design as closely as possible, we also consider the complexities of whether the joints are strong enough, whether we can use existing products for cost considerations, or whether we need custom-made machined parts, and then we put this into the production drawings. Once the drawings are in our hands, we meet with the client and the design team to ensure that there are no problems with understanding. With these processes in place, we then proceed to the actual in-factory process. Many of the products we make are also one-offs, which are characterised by their craftsmanship and finish. Therefore, a somewhat different mindset and methodology is required to cope with the mass production of the same quality in large quantities.

Continuous handrail stiles

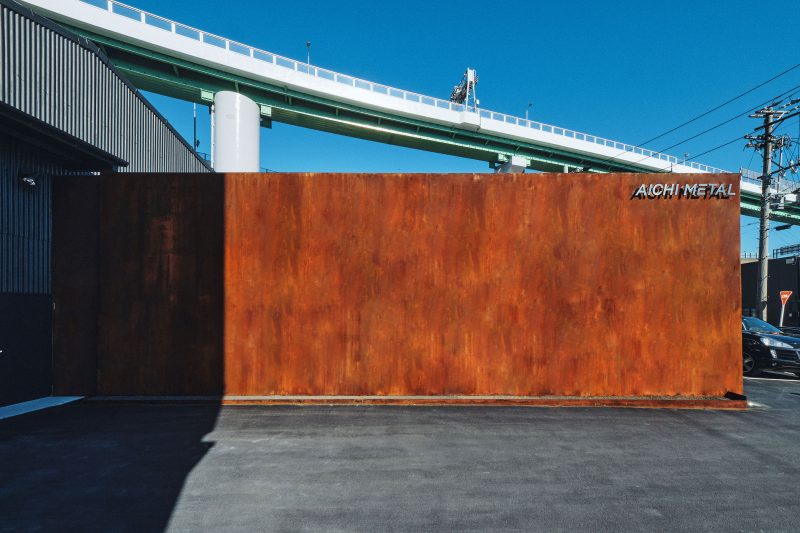

AICHI METALS also has a track record of manufacturing mass-produced products of consistent quality. One example is the manufacture of window sashes, which AICHI METALS was involved in at the time of its foundation. These were half-standardised products that were continuously mass-produced. Of course, even today, we have accumulated a lot of know-how in this field. That is why we are able to respond to orders for large-scale commercial buildings and public buildings such as this one. AICHI METAL’s ability to respond to customer needs can be attributed to the fact that we have both processes in place – the process whereby our craftsmen finish the product from the product drawing and the process whereby we finish mass-produced products to the same quality. Please leave it to AICHI METAL to provide components for large-scale buildings such as offices, commercial facilities and public facilities.