AICHI METAL

Case Studies

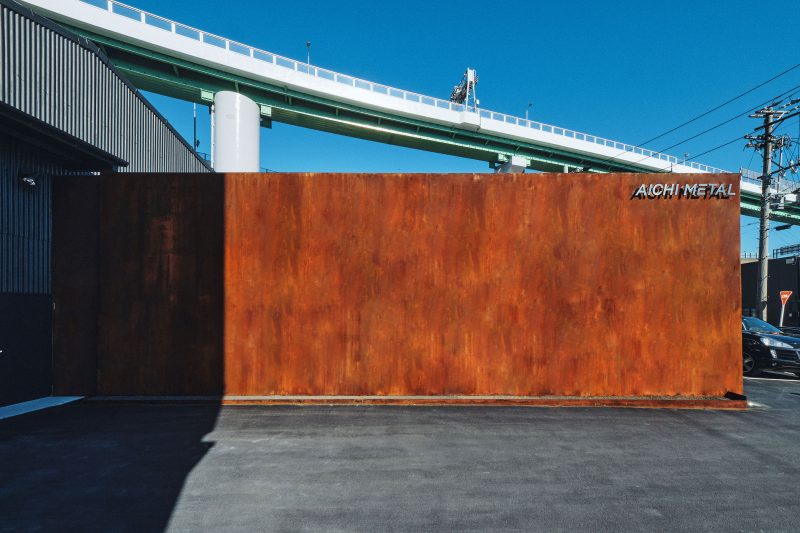

An office, whether large or small, serves as the face of a corporation. In the case of projects that come to us, mainly for large offices, the basic interior component requirements are more common. These are requests for metal components around reception areas and relatively large sizing components such as interior office walls. More recently, we have also seen an increase in components that cater to diverse designs, such as internal staircases and railings. For small and medium-sized offices, it is more diverse. In some cases, we can provide the external walls, in others, the staircases and even the furniture. The main difference with housing is durability. Of course, the requirements for housing are sophisticated, but in the case of offices, the requirements are based on the fact that the number of people who come into contact with the office is significantly higher. This project is a single office building that has been carefully designed. The products involved were both exterior and interior, including exterior walls, doors, intercom panels and staircases. For the exterior in particular, the order was to create a look using a phosphating treatment process, so we focused on establishing a method that would allow the product to withstand the elements and retain its good quality for a long time.

“What we should represent” and quality

When working on several important items in one property, the key question is how to ensure a sense of ‘unity’. The techniques used in this project are truly complex. Bending, assembly, painting, phosphating… the list goes on and on, but each one has its own important quality controls. The benchmark is what the property “should represent”. Based on the understanding that has been developed in the course of shared discussions with the architects, quality control is carried out in a unified way, using different techniques with gradual tuning. Take colour, for example. It is of course possible to standardise only the colour of the finished product, but if, for example, there are large differences in the process when considering ageing, problems are likely to occur when the property is finally built over the years. Of course, it is difficult to calculate everything for decorative metal treatments, as changes over time vary greatly depending on the location and time period, and maintenance will occur more than once. Nevertheless, we believe that it is significant that we take this into account during the production phase of the process.

The finished product is all harmony

This is not to say that we, the companies who supply only some of the components, are not responsible for the finish of the building. In the end, it is the harmony of the individual components that counts. We believe that a building is the ultimate creation, which is the result of precise calculations and the accumulation of finished products. The concept of maintenance is also important. Even after completion, if there are any changes to the components we have worked on that are of concern, we place great importance on checking them immediately on site. This is because changes after completion can lead to a review of the quality of the process. Even components, especially those that appear on the surface of a building, play an important role in determining the overall intent of the building. Can we face the process with an image of the finished building on the other side of the component? And what should be our quality? Our thinking is also deepened by taking into account the individuality of buildings that welcome a wide range of customers, such as this office in particular.