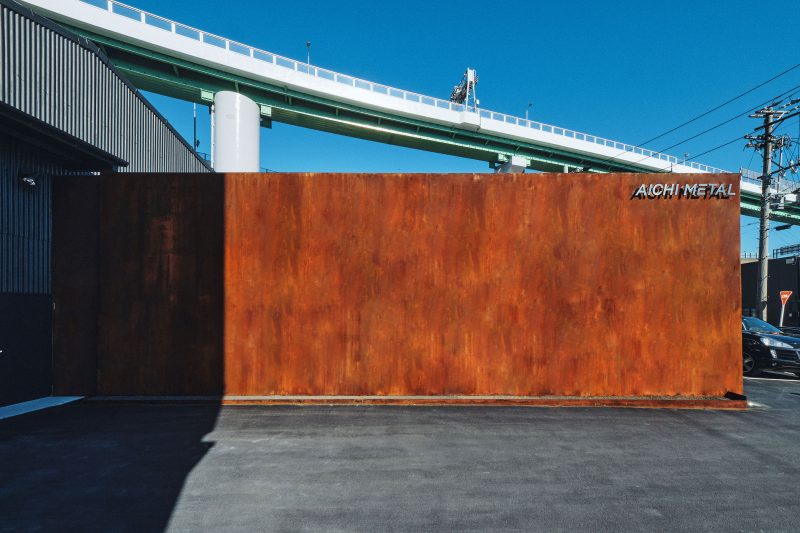

Nagoya City, Aichi Prefecture

Industrial company buildings

Phosphating steel is a very popular decorative treatment. It is now a relatively popular treatment, but the most important aspect of this decoration is quality. One of the most common enquiries we receive these days is that, in an increasing number of cases, components that have been installed after phosphating have become cloudy or discoloured within a few months. This is a case where either some post-processing has not been carried out after the phosphating treatment, or it is a separate treatment that only results in a phosphating-like expression in the first place. It is difficult to tell the difference at the time of delivery, and it is necessary to work with a company that implements the process treatment with careful quality from the outset. In this case, it was a tremendous challenge to attach these phosphate-treated components to all the walls of the building. If they are attached to the surface of a building, the area exposed to wind and rain is naturally extraordinary. Furthermore, the volume of the materials is also unbelievable. On the other hand, the presence of the building as a whole is dramatically enhanced, and the toughness of the building is increased because of the metallic surface. From the materials to the decorative treatment and all quality control, this was a rare project for AICHI METAL.

A collection of diverse metal expressions

It is not only the walls. The interior materials for the entrance area and the iron frames for the huge glass inserts as the exterior of the entrance are all processed and treated by AICHI METAL. It was a great honour to be involved in the metal treatment, which plays an important role in the costume aspect of this building. Naturally, the responsibility is also heavy. The precision of the window surface steel sections had to be extremely high. Needless to say, the fitting of the glass surfaces was of great importance, as the design is based on structural calculations that take into account earthquake resistance. In addition to the varied metallic look of the phosphating treatment on the walls, the black steel frames give a tighter look. The steel frame is treated with a matt coating, but as this is also an exterior finish, we have incorporated a variety of know-how to prevent the paint from peeling off. After treatment, everything is shipped to us, so we carry out careful quality assurance inspections.

The idea is to capture the intention

In projects such as buildings, it is rare for us to carry out on-site work. This is particularly difficult when it comes to external walls. However, it is possible to conceive of the construction process. This means that we can imagine the design and construction process and take into account the intentions of the project. We consider this part of the process to be very important. But on the other hand, this is always difficult, and sometimes difficult to realise perfectly. Communication is essential. How will it be constructed, how will it be finished, how long is the building intended to last, what is the level of seismic resistance and robustness? We can only commit to a small percentage of all this, but it all depends on this communication to be able to process and understand the project as a whole. As well as striving to build good relationships, it is also important to clarify our position by not being afraid to communicate what we think. For us, that is what metalworking is all about.