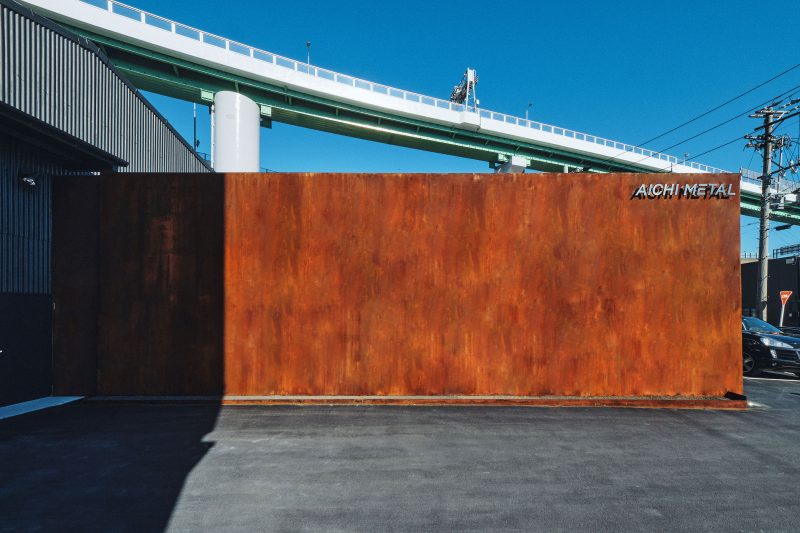

Aichi (Aichi Prefecture)

Technical Case Studies

AICHI METALS is working on the establishment of in-house technology for the anti-corrosion treatment of steel, and is carrying out various research and development activities. Products with delicate designs, such as gates, sashes and lattices, which are used outside and have steel as the base material, are coated with zinc using thermal spraying technology. The greatest benefit is that the product is not subjected to thermal stress, which prevents accidents such as distortion and breakage, and also significantly increases the adhesion of the coating. Furthermore, as a unique surface texture is created, this can be used for an unlimited number of decorative treatments. However, there was an accident that led us to this technology.

Experienced accidents due to hot dip galvanising

Originally, we used hot dip galvanising. This involved placing the product in a galvanising tank and immersing it in hot molten zinc (approx. 440°C – 460°C), which caused distortion accidents due to the heat. As with any material, distortion is difficult to remedy. This is especially true for delicate products. The cause is that some shrink and some stretch, each of which is irreversible due to material transformation. Rust prevention by hot-dip galvanising has proven to be an excellent technique for preventing rust on steel. This is where we arrived at thermal spraying technology after exhaustive research.

Overcome distortions caused by hot dip galvanising

Zinc coatings have a long history. Therefore, the solution was already out there. However, the fact is that fields such as ours rarely use that method. As a result, the introduction of zinc coating technology by thermal spraying has drastically reduced the number of incidents such as distortion. These efforts have created a certain awareness in us. There is a vast amount of human wisdom in the society, which is far wider than our field, if we include history. Whenever we get stuck, there is almost always a solution already in place, which we have not yet encountered because they are considered to be ‘specific to a particular field’. This means that we have not yet met them. This fact is also the basis on which we continue to do R&D.