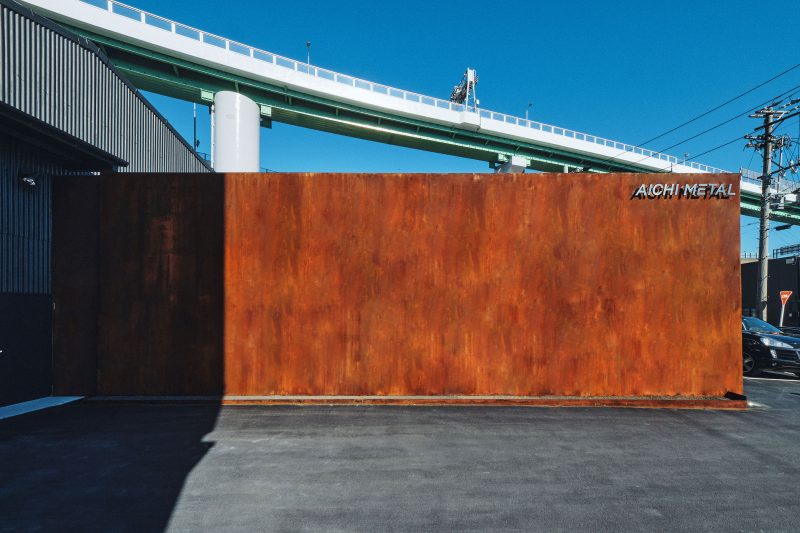

AICHI METAL

Technical Case Studies

This project is, in any case, an extremely impressive case whose elegance stands out in the huge circular space. First of all, the building has concrete walls and a floor of marble with a characteristic marbled pattern, showing the thorough attention to detail in the materials. This is complemented by a jet-black metal frame with an exquisite design and a staircase with white stone treads. Although the staircase itself was designed by AICHI METAL, it has a number of distinctive features. The gracefully curved shape of the frame is particularly noteworthy. The same applies to the degree of difficulty. The large, curved inner and outer diameters are naturally different in size, but the treads must be fixed in position, so that even the slightest misalignment in the installation location can cause the person using the staircase to lose their sense of equilibrium and render it unusable. The tension of accuracy inspections, which cannot fail, was at a level that is difficult to experience.

Consistency and tension

We cannot cut corners every time on the quality that we have to fulfil, not only in this project but also in other projects. We are a company that makes components, but we also process the very safety of society. That is why we must be consistent with precision. In addition, multiple projects are running in the factory, so process management is directly related to safety management in society. At AICHI METALS in particular, there are many manual processes, and the understanding of the craftspeople is always required. Of course, we use various machines in the process, but we cannot leave all the finishing touches to machines. This is one area where we can be sure that even with the evolution of AI in the future, there will still be a great deal of reliance on human labour. AICHI METAL’s quality lies in the consistency of all these aspects: the tension in the factory when assembling one component at a time, and the finishing, adjustment, inspection and quality control of the on-site construction.

Significance of existence changing with construction

This staircase was also quite challenging to construct. The size and weight of the staircase, as well as the accuracy of the curves, made it an extremely important part of the on-site installation. The sense of achievement on completion of the installation is indescribable. It reaffirms the fact that architecture is a collection of technologies and materials that maintain a perfect balance. In our factory, every item is just one component of many. They become more and more present as they go through the process, and we pay more and more attention to their touch. However, they are only complete when they are used in construction, so even if we have completed all the processes in our factory, they are not complete by themselves. In fact, that is where our responsibility lies. The fact that we are involved in on-site construction is certainly an expression of our desire to deliver the product while fine-tuning it on site. However, in essence, it is only by experiencing the space itself and experiencing the ‘completion’ of the construction that we are able to fully understand the client, the construction and the processing from order to delivery. This is how we are constantly refined.