Tokyo

Technical case studies

Electric locks and controls

The electrification trends coming to cars are having a transformative impact on society. Social innovations such as MaaS and CASE are only accelerating. Even in jobs that, like ours, seem to have no connection to such things, the telecommunications wave is definitely coming. For example, the IoT trend is progressing rapidly, even for a single door, lock or indoor climate control. In our case, the IoT trend is certainly sweeping over items that we provide as finished products, such as gates, functional gateposts and doors, using ready-made products. The other day, we had an experience that made us acutely aware of this trend and the difficulty of responding to it.

Electric lock installation and metalwork installation

It was a project we worked on where we fitted an electric lock to a door. Normally, a door is locked with a key and handle, but in this case it was an electric lock. Therefore, electrical treatment is required. However, we don’t have the know-how in electrical work and this is basically something that is done professionally by other contractors. In this case, this part of the project was difficult to deal with and we had to do the electrical grounding and the actual installation as well. Naturally, problems arose. Simply put, the electric lock did not work. At this point, we realised that it was difficult to find the cause of the problem.

Responsibility and trust

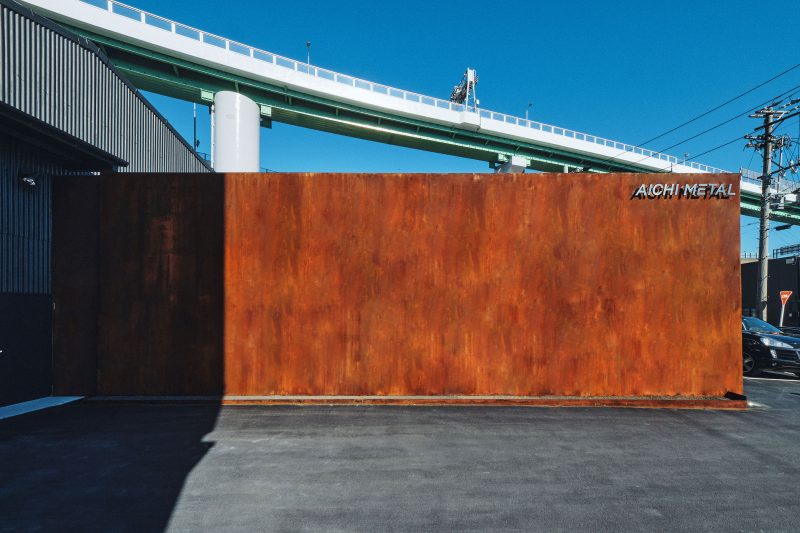

With regard to the products used in this project, although mutual connection compatibility is theoretically guaranteed by a standard called the JEM-A (Jema) standard, it was difficult to judge whether they would work well as we had no experience with them. Even when we contacted the respective manufacturers to check the actual product compatibility, it was difficult to get a clear answer, as it is difficult to check compatibility with all products on a manufacturer-by-manufacturer basis. In the end, AICHI METAL, whose core business is not electrical work, had to bear the final responsibility, which is another point we regret. However, from the customer’s point of view, it is natural for them to outsource to us in terms of functions associated with the door. If we were to say that these projects will be zero in the future, or that we will not accept them, we would lose the chance and the challenge to adapt to a changing society. This has been a great gain. We are now taking action on this electrical knowledge. We feel that the metalworking industry, which is indispensable in an ever-changing society, is being questioned.