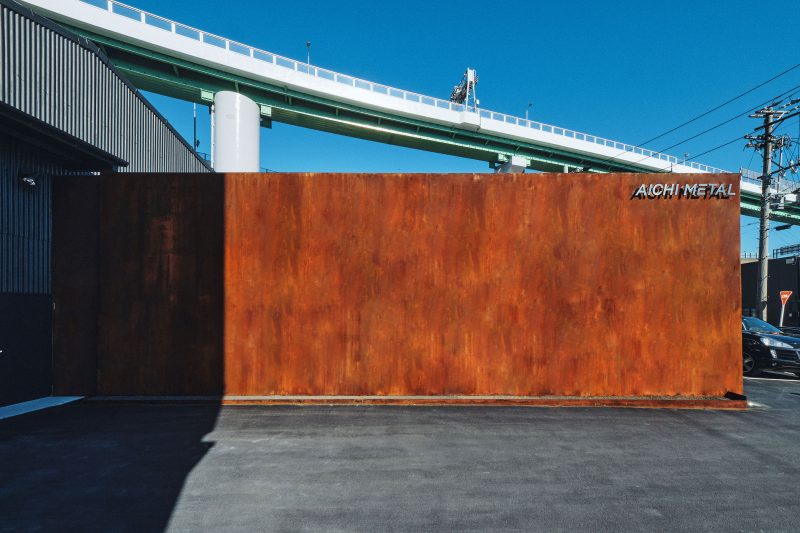

AICHI METAL

Technical Case Studies

Electronic control is a word with a thousand different methods and mechanisms. At first glance, it may seem like a world that is out of reach for those of us who work in metalworking, but it is a technology that is right next door to any other field. For example, when we make an elevator door, it is a large electronic control unit, and we are making the face of the elevator. However, the electronic control itself is not assembled in our company. However, we can talk about ideas and construction concepts. And we can also shape them with the help of external partners. After all, there is always a way to realise it.

A world like a place

This project was the production of furniture. The furniture has a hand wash inside it. Therefore, if the hands are wet when opening and closing the door, the door part will be damaged faster. Furthermore, the constant concealment of the water area can create a new tension in the space. We came to the conclusion that the best option to fulfil these elements was for the door to detect people and open and close automatically. In fact, a single metal door is installed in the president’s office and the external entrance area of AICHI METAL. This is designed to be opened using a code. The door was custom-built by us, and the company that assembled this electronic control was also our partner. So we gave them our requirements and they decided to develop the electronic control part.

Simplicity and understanding

The resulting electronic control is extremely simple. The automatic opening and closing of doors is not an unusual mechanism in itself. However, when it comes to a piece of furniture that is placed inside the house and also contains a hand wash basin, the mechanism becomes very special. A control panel assembled from a circuit board is combined with a motorised mechanism to open and close the door at the top of the door. The movement was designed to be smooth. It’s really simple, but by adding the specs of electronic control to the realm of metalworking, we also get a new expression. New challenges, including future maintenance, are always a great reminder.