Aichi (Aichi Prefecture)

Technological Development

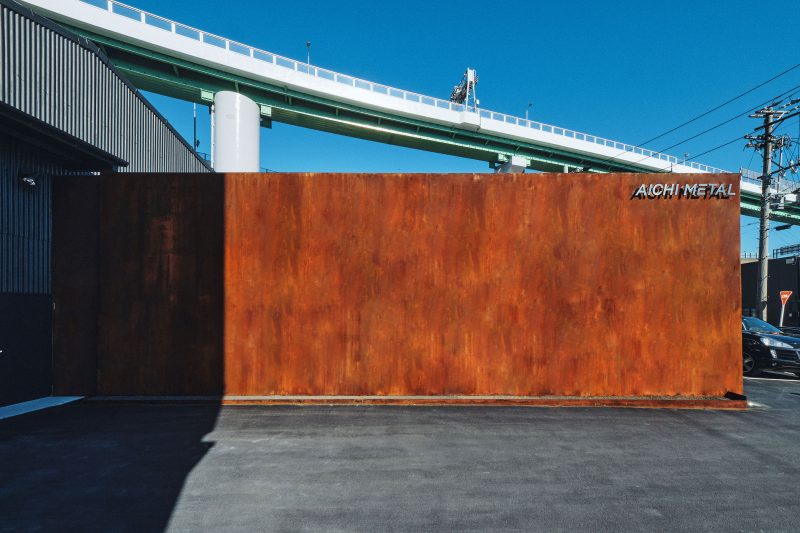

“Metals bring a tasteful look with age”

What is black iron?

Black iron is one of the most popular metal expressions. In particular, black iron skin, produced by a process known as hot rolling, is covered with an oxide film, which is popular for its strength performance and colour, and can now be found in use in a wide range of situations. The characteristics of this manufacturing method are as follows. ・The steel is rolled at temperatures between 900°C and 1200°C, making it easier to process than other metals. ・It is also superior in terms of cost performance. The opposite of this method is cold rolling. This is also popular, but while this material has a very smooth and shiny surface due to the absence of an oxide film, it is also very prone to rust, so the surface must be protected at all times.

Preferred but difficult material to handle

The reason why black iron is so popular is that it has a look and feel that cannot be achieved with paint. The texture of black iron will increase with age. By using the black iron without a topcoat, a tasteful look is achieved. While it is possible to enjoy the changes in expression and texture over time, black iron is also prone to problems. Black iron can be used as a surface material as it is, but it has the disadvantages of being ‘scratched from the time it comes from the mill’, ‘sparsely patterned’ and ‘rusts easily’. It is also a matter of skill for us to manage the problems that black iron is prone to. For example, it is possible to express a comparable black skin by shot-blasting welded, cut and polished black skin products, decorating them with a decorating agent developed by us and top-coating them. This can significantly increase reliability.

Black iron-finish with special coating and VeroMetal HD black-finish

Furthermore, the use of the special coatings ‘VeroMetal’ and ‘VeroMetal HD’ enables us to produce black iron skin at a level we can confidently offer. The black skin on the surface of iron is formed at a high temperature of approximately 1000 °C, and when the temperature drops, the surface oxidises and a film is formed. However, with black iron with VeroMetal, shades of colour can be freely adjusted. Using this, we have accumulated many examples of decorative treatments with black iron-finish and are proud of our extensive track record. Of course, we have not only achieved corrosion resistance after finishing, but also ageing performance. We are well equipped to bring the appeal of black iron to a large number of people.