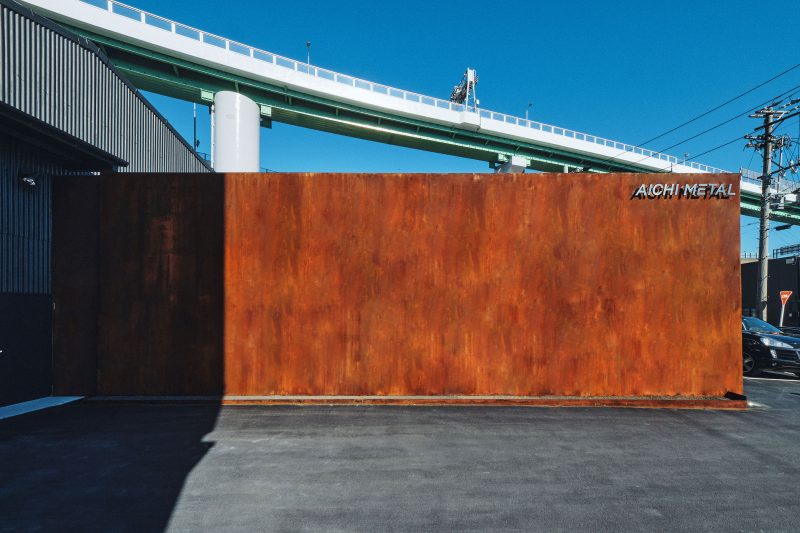

Aichi (Prefektur Aichi)

5S and metal

Storage of products and screws

5S (Seiri, Seiton, Seiso, Seiketsu and Shitsuke). Widely known as an excellent motto for environmental maintenance, this term has spread not only in Japan but also globally. We too have been focusing on ‘5S activities’ to improve the environment in our factories and warehouses (e.g. packaging workspaces and product storage areas). Nevertheless, these activities, which had been getting squeezed by daily work, were strengthened at once when we had some free time after the Corona disaster. We have made significant progress in the past few months. These have had effects that go beyond mere environmental improvement. For example, the visualisation and tidying up of the 5S activities have proven to be even more effective in the construction measures using the same materials, which are necessary to prevent electrolytic corrosion caused by different materials. Furthermore, the risk of contamination with different materials has been drastically reduced due to a drastic reduction in the ordering of unnecessary parts and materials, leading to shorter inspection times and other tangible benefits.

Intrinsic effects of visualisation

It is easy to say in one word ‘visualisation’, but in promoting 5S, we have come to realise the difficulty of achieving this and at the same time the enormity of this effect. At the same time, the process of implementation has the effect of generating ideas within the company. For example, the visualisation of components naturally reduces the time spent searching for them. Secondly, it has saved us from having to order extra parts and materials, and we now know how much stock we have of the same parts, which used to be scattered around the company. Staff who have experienced this effect have come up with ideas for the next time, and the next time, and the next time, and so on. It would be obvious to say that this is a matter of course, but this was a scene that was not easy to realise. The reason why it is easy for all the people – frontline people, sales support people, finance and management – to actively participate is because they can see the effects being created in areas that are simple but unnoticeable. We have been ISO certified for 10 years now, and in that time we have understood the same things as knowledge, but now we are responding to the fact that we have come to the part where we can realise the same things with practice in the future. We will continue to strive to constantly improve our corporate quality.