Aichi (Aichi Prefecture)

Technological Development

Towards lighter metal panels

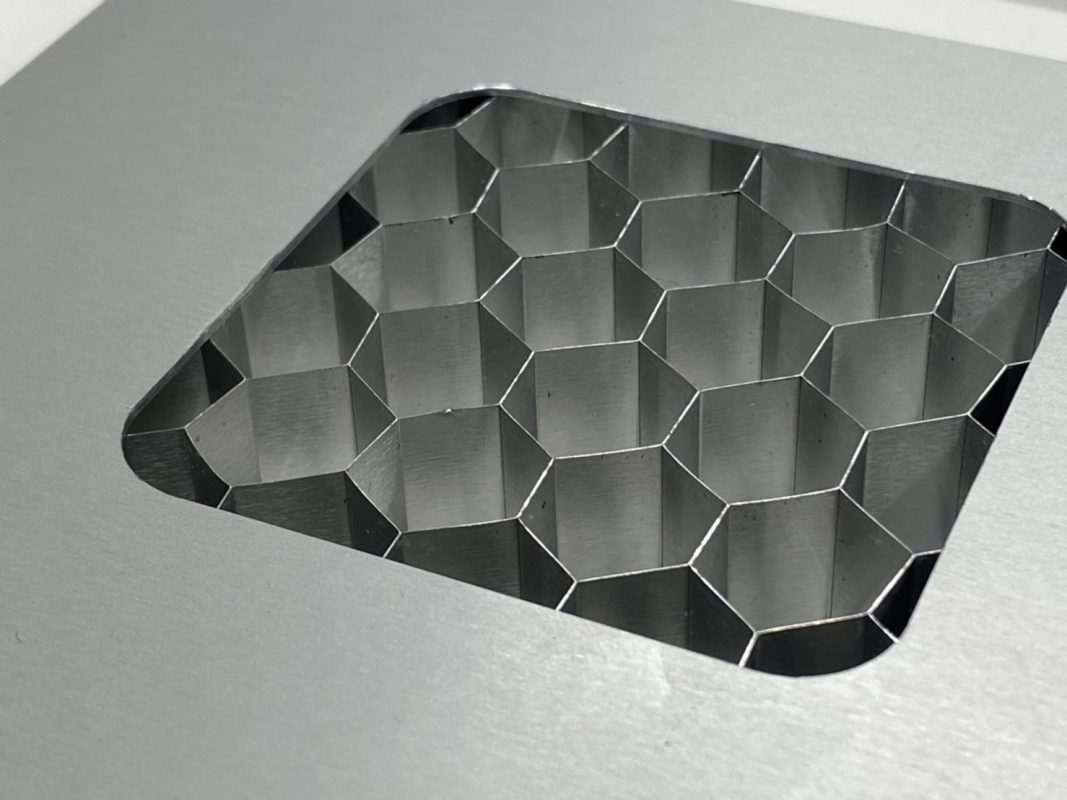

AICHI METALS has traditionally used steel or stainless steel for panels when manufacturing conventional external functional gatepost panels. In doing so, we have struggled with the choice of materials to be used as the base material. This is because weight is a challenge anyway. The more we try to increase safety and reliability, the more we cannot stop the trend towards heavier weights. If you reduce the weight, you lose the strength. However, through a truly fortuitous encounter, we found a solution to this. This is the use of a honeycomb structure. Honeycomb structures themselves are not at all unusual. Even the world of corrugated cardboard has adopted these for strength. However, the reason why we have not adopted this is that it is extremely difficult to process small edges. This is because in the case of metal, a single small edge can cause serious injury to a person.

What is honeycomb?

The term ‘honeycomb structure’ is derived from the structure of a honeycomb. This is extremely complex to understand mathematically, so we will venture to describe it as a collection of regular hexagons. This ‘honeycomb core’, which is a structure that combines regular hexagons, is used in a wide range of situations as a structure that can “make efficient use of materials while also maintaining a certain level of strength” and requires as little material as possible without compromising strength.

The coincidence was that a company we have known for a long time had the technology to use this honeycomb structure to treat the small ends in a wonderfully clean way. If we could apply this, we would be on the right track to reducing weight while increasing strength. Once honeycomb panels have been achieved, surface treatment is AICHI METAL’s strongest area of expertise, making it possible to create lightweight, strong and beautiful-looking products made entirely from metal.

Lightweight and strong honeycomb panel

In fact, there were already such products in society. It is just that there were not so many examples of applications in the fields of architecture and furniture. Now we are working on the commercialisation of these products. It is not that difficult, though, and we are already in the process of trying it out on a case-by-case basis. The honeycomb core used in the honeycomb structure is also made of aluminium, which can deal with corrosion problems. There are countless examples of social technologies that already exist, but are unknown in different fields. We, too, have sublimated into the current accumulation of technology through such encounters. It is exciting to think that there are still more such encounters to come, and the fact that there are still more places to hone our technology makes us confident of future evolution and growth.