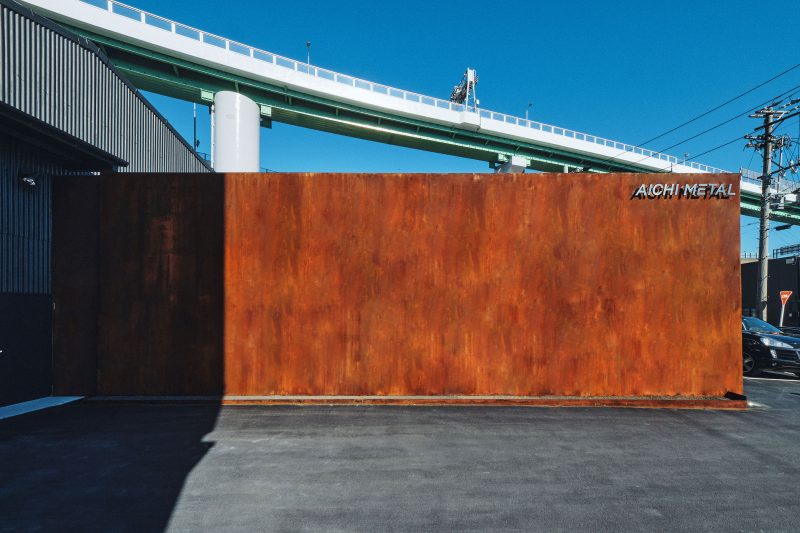

AICHI METAL

Technical Case Studies, Case Studies

Entrances are mysterious. It is both an entrance and an exit, and no matter how huge a house or building is, people always look for the part that is the entrance. Therefore, no matter how small or large, the entranceway always attracts attention. For this reason, many owners are particular about the materials and finish of their entrance, and we receive many requests for entrance finishing. The basis of a doorway is a single board made of several materials laminated together. Of course, it is useless if there are gaps when it fits into the building. Therefore, it is packed with various dimensions and design quirks. The same applies to this project. Particularly important are the basic techniques, such as making sure that the door handles are exactly parallel to each other, as they are of a type that is installed across the full length and width of the doorway.

Clearcoat method development

This door also benefits from the power of AICHI METAL’s research and development team. This is the clear coat treatment. The doors are first treated with zinc to prevent corrosion and then bronzed with Verometal® HD. Then, after an oxidation process to create a decorative irregularity, a clear coat is applied to increase the strength of the door. However, the clear coat was a major challenge. Many building materials are designed to be damaged, so durability-oriented painting methods are the norm. From this point of view, the decorative treatment of metals is an extremely delicate category, so the finishing coatings are of particular importance both in terms of durability and ageing. Nevertheless, we have found that clear coats in the architectural sector can significantly detract from the good qualities of the decorative treatment. In order to find a clear coat that would meet our needs, our research and development team tested and verified various products before arriving at the optimum clear coat and establishing its utilisation through various efforts.

Layers of toughness

The overall process is to first corrosion-proof with zinc, then decorate with bronze and oxidising agent technology, and then create toughness with a clear coat. Each of these processes is subject to thorough quality control by experienced staff. The result is a dramatic change in the look brought to buildings. Doors in particular have a unique presence. It is precisely because of these components that our technology can also take on new meaning. Metals still have unlimited expression and potential. We are refining our technology to realise them.