Technical Development Areas

AICHI METAL × Technology

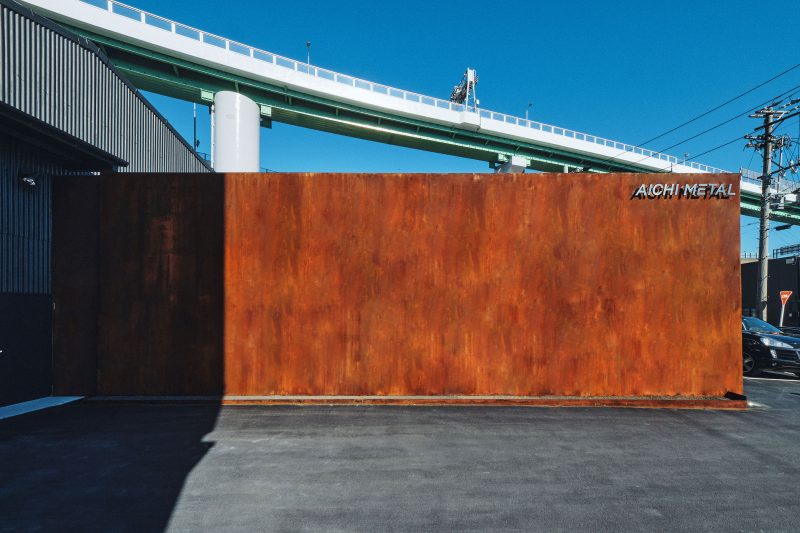

There are several phases of construction, but our turn comes much later. After the structural aspects such as land preparation, foundation construction, structural construction and wall construction have been completed, it is time to move on to the finishing process. These finishes also vary. Our metal components appear amongst the cross-laying, decorative boards, plastering, concrete, etc., etc. For example, everything from our steel gates, railings and stairs to surface-treated metal sheets can be categorised here. As all building components are brought to the site and assembled, they are always prone to scratches and minor dents at any stage of the process. This can never be eliminated, but it is a construction convenience no matter what. The same applies to the finishing process: if there is a slight clash of materials on the site, it is impossible to ignore it. Therefore, our own staff go to the site to manage their own materials and carefully assemble them. We also have the know-how to repair minor damages on the spot.

In search of a beautiful paint job

What even we cannot prevent are the forces of nature. In particular, wind and rain are already overwhelming. It wears away all materials, not with the force of the moment, but with the force of continuity. In our case, the surface-treated metal sheet coatings used on exterior walls are constantly facing this challenge. Nevertheless, the look of a building becomes tasteless if it is simply a metal sheet. That is why we are constantly pursuing methodologies for surface treatments and surface coatings. However, in the realm of the building sector, painting technology is not at such a high level. We therefore searched for a coating method that would be thoroughly beautiful and durable at the same time. What we finally arrived at was a surface coating for cars. The representative of the company, Yamada, had a friend who runs a car repair shop, and his story gave us a hint. The paint on cars remains beautiful even after continuous exposure to the elements. This is because the fundamental concept of painting is different from that of construction. At the same time, it is a tremendously expensive process from the architectural field. At first we outsourced the work, but eventually we built a system where all the equipment was installed in-house and the painting could be carried out. This enabled us to provide high-precision, highly durable coatings at a somewhat reduced price.

New ways of using thermal spraying

And now, as a result of our efforts to find further ways of utilising it, we are also working on new uses for an old method. This is thermal spraying. This is a method of spraying molten metal, and the method itself is not brand new. The reason why AICHI METAL is working on this is that the metal is melted at hand, so there is no damage to the base material itself, such as distortion or warping caused by heat, and in the end the coating is applied more firmly to the surface. Thermal spraying creates an uneven surface on the metal. This is where the paint base material is firmly engaged, making it possible to achieve a treatment that is almost impossible to peel, even for the most delicate of paints. This allows us to experiment with new surface treatments. This includes decorative treatments, rusting, polishing, phosphating, etc., as well as a wide range of materials such as stainless steel, iron, brass and copper. Once a thermal spray treatment is applied to the substrate, the subsequent durability of the product is completely different. No compromises are made on the façades of many buildings where beauty is a must.